The performance of an anode is one of the most critical parameters in maximizing efficiency in electrorefining and electrowinning copper, zinc, cobalt, nickel and manganese. Our advanced rolled anode blades have sophistically controlled grain structure to have better corrosion resistance and mechanical stability. Its most optimal design of alloy content can reduce the end user’s capital investment but while maintain optimum current efficiency and remain longer service life.

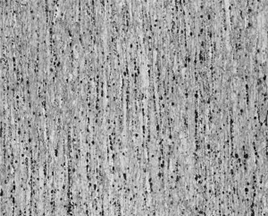

Cold rolling after casting further improves the productivity and life span of our anodes. Rolling breaks up the grain structure, elongates and orients the grains which become more homogenous in terms of alloy distribution. This is not only improves the conductivity but it also:

Further reduces porosity

Enhance corrosion resistance

Prevent creep

We had developed a surface finish to optimize electrowinning performance. Our environmentally safe surface pre-treatment for PbAg anode ensures it rapidly generate a thin, adherent film of PbO2 on the rough irregular surface with a deep indentations of up to 1 mm.

We can produce PbAg anode from 1.6 to 3.6 m2 with silver content as low as 0.5%, PbCaSn anode and cast PbSb anode.